Anti Tipping Mechanism Design

for a wheelchair

It is evident that wheelchairs have become an important part of today's world. Although being an effective and powerful assistive technology it still needs attention in the field of user safety, especially for those who are suffering from Alzheimer's disease, Parkinson's disease, cerebral palsy etc. The design presents a mechanism which addresses one such safety issue i.e. sideways tipping while cornering. The mechanism is designed for a upper level project which is smart enough to identify the fall characteristics beforehand and deploy itself without human intervention.

The natural instinct to a safe turning is reducing the speed. Our approach is different in that it addresses this problem without any decrement in speed. The main motive of this research work was to devise a mechanism that not only provides prevention against injuries while cornering but also to make them a faster medium of transport.

The whole idea is to shift the point of tipping and provide a much broader stance. A similar thing is provided with cambers in case of racing wheelchairs but at the cost of wear at the inner side of the wheel and also a wider base which creates difficulties while moving through doors or narrow spaces. So to counter the difficulties the mechanism is inactive while a straight path motion thus preventing any space requirements and activates automatically while taking a sharp turn thus providing the much needed stability. The mechanism is actuated by a solenoid and works on a feedback loop from a tilt sensor which identifies any rolling action that might occur and pushes out an extension arm to support the wheelchair.

Details of the Mechanism

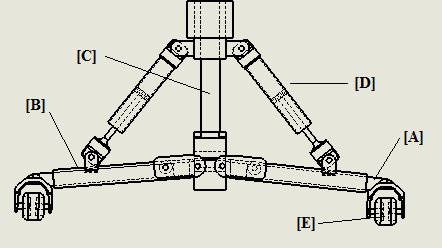

The figure to the left shows the schematic

sketch of the mechanism. The entire mechanism consists of five

parts. The slider/ extension arm [A], the slot

with solenoid actuation [B], the fixed part

attached to the wheelchair [C], damper [D],

and finally Caster wheels [E].[B] is provided a revolute joint to be attached to

the part [C] and houses the extension arm [A].

The revolute joint is necessary to provide the

mechanism with necessary flexibility and also to

ensure that the outer wheel (of the wheelchair),

the caster wheel (of the wheelchair) and [E]

remains at the level ground thus preventing the

possibility of single point contact in the case of

cornering.

The figure to the left shows the schematic

sketch of the mechanism. The entire mechanism consists of five

parts. The slider/ extension arm [A], the slot

with solenoid actuation [B], the fixed part

attached to the wheelchair [C], damper [D],

and finally Caster wheels [E].[B] is provided a revolute joint to be attached to

the part [C] and houses the extension arm [A].

The revolute joint is necessary to provide the

mechanism with necessary flexibility and also to

ensure that the outer wheel (of the wheelchair),

the caster wheel (of the wheelchair) and [E]

remains at the level ground thus preventing the

possibility of single point contact in the case of

cornering.